Overview

Nestled in the heart of California wine country, Montage Healdsburg is a luxury resort that delivers an immersive and refined experience across 258 acres of rolling hills, oak trees, and world-class vineyards. Opened to the public in January 2021, the resort is celebrated not only for its five-star hospitality but also for the complex engineering and design journey it took to bring it to life. As the structural engineer of record, ISE Structural Engineers played a pivotal role in overcoming a series of design, site, and construction challenges throughout the project’s multi-year lifecycle.

Project Timeline and Evolution

The project’s early stages began in December 2015, when ISE received initial files from Blu Homes. By March 2016, the first state plan sets were underway. Initially envisioned as a modular construction project, the resort’s design transitioned from CAD to Revit later in 2016 and went through several strategic shifts—from Blu Homes to JLC Modular, and eventually, to site-built panelized construction by mid-2018.

This shift marked a significant turning point. After more than two years of modular coordination, the project pivoted to panelized construction just three weeks before breaking ground. These transitions placed significant demands on the engineering team, ultimately requiring 446 hours of original design service and 511 additional hours over 17 Architectural Services Requests (ASRs) after the initial permit.

Site and Foundation Complexity

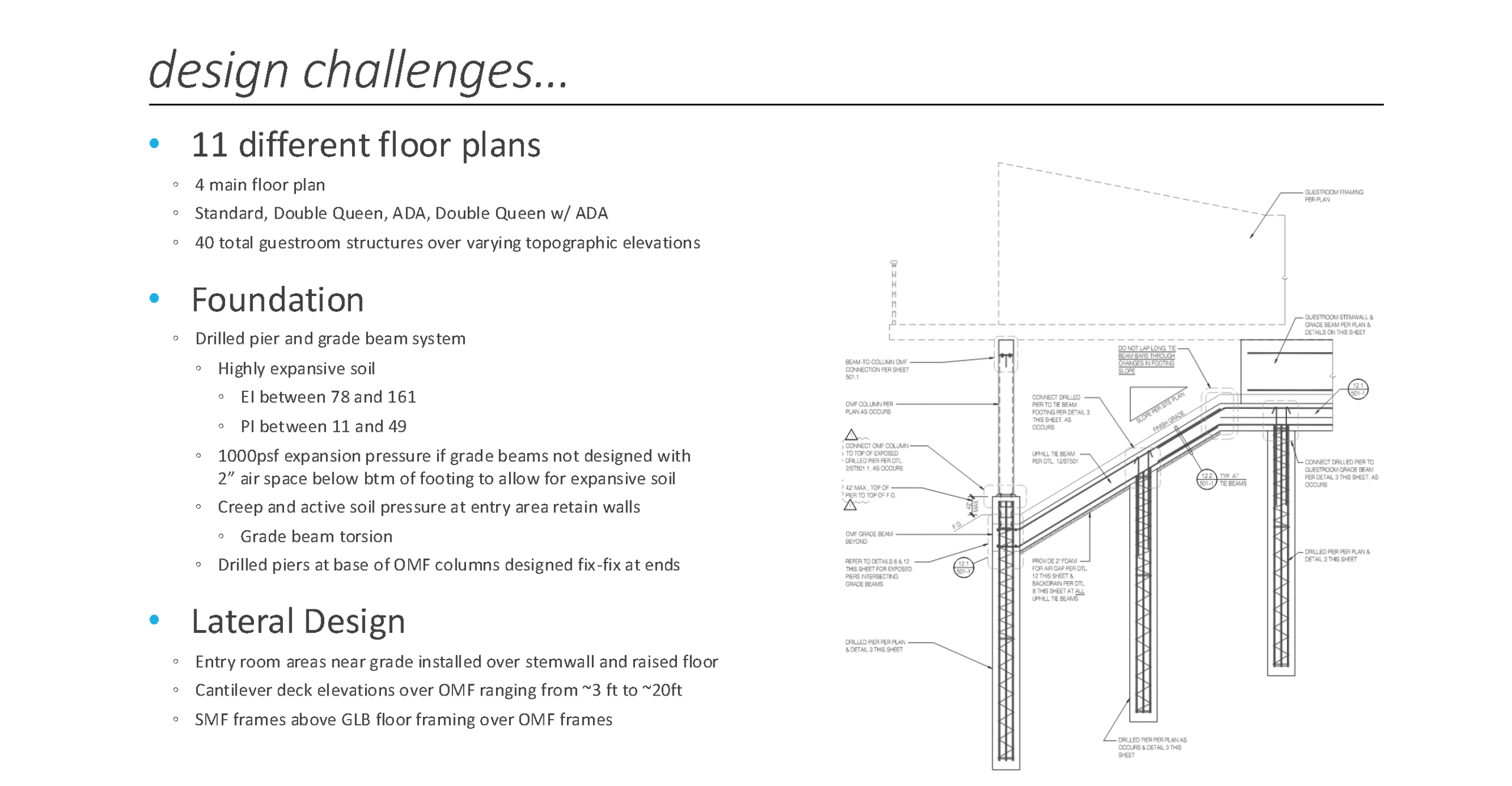

Montage Healdsburg’s scenic location came with substantial geotechnical challenges. The topography featured highly expansive soils, with Expansion Index (EI) values ranging from 78 to 161 and Plasticity Index (PI) values between 11 and 49. These conditions required a carefully engineered drilled pier and grade beam foundation system designed to mitigate the risk of soil-induced structural movement.

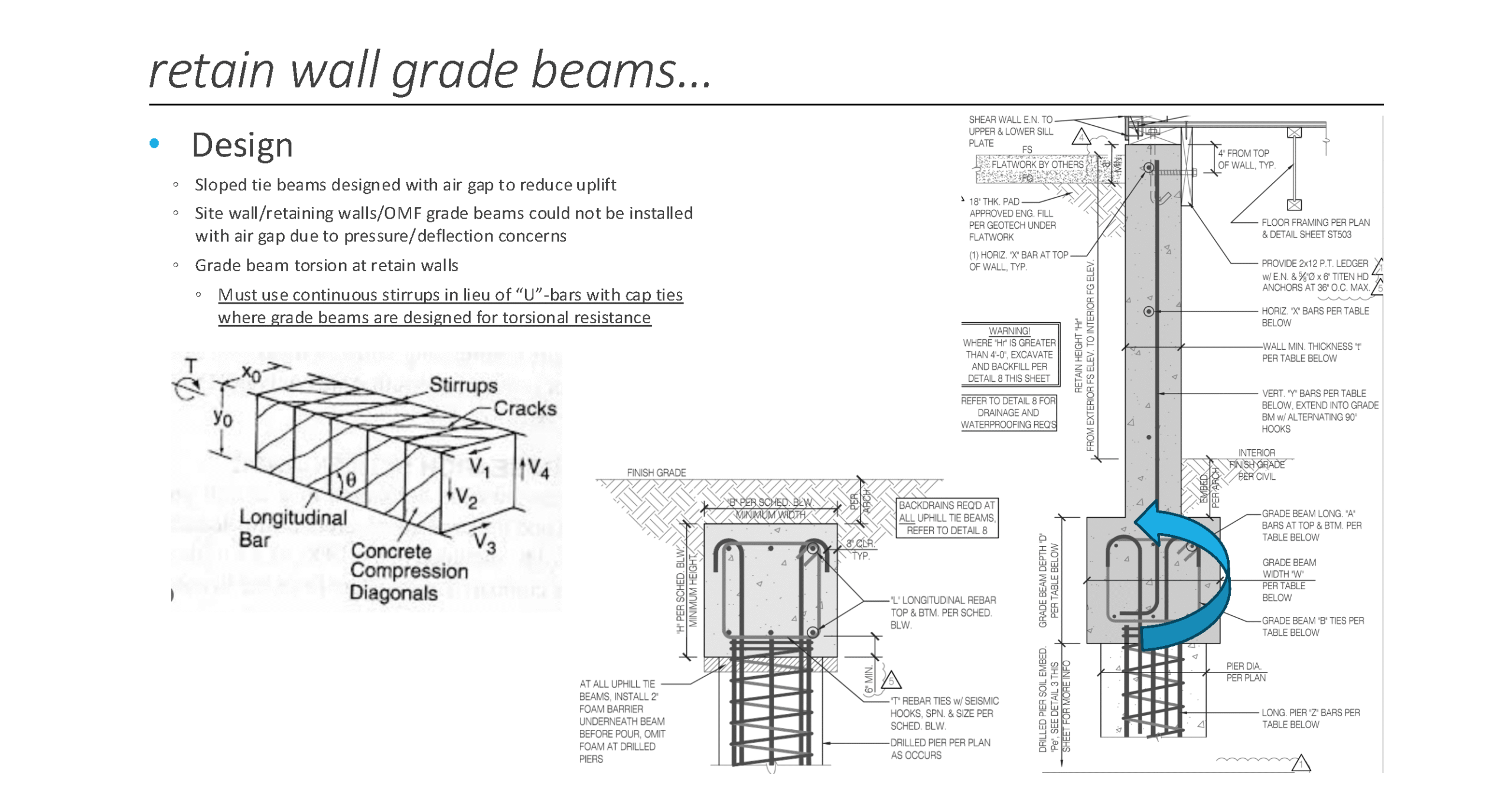

Special attention was paid to allow for an air gap beneath the bottom of the footings—a critical detail that prevented up to 1000 pounds per square foot of expansion pressure from acting on the grade beams. In areas where this wasn’t feasible, particularly around retaining walls, grade beams were reinforced with continuous stirrups instead of traditional U-bars to resist torsional forces.

Unique Design Challenges

The architectural programming included 40 individual guestroom structures spread across varying elevations and featuring 11 different floor plan types, including ADA-compliant configurations. Each unit had to be adapted to the terrain and comply with stringent accessibility and performance standards.

From a structural perspective, the complexity extended to cantilevered decks, sloped site walls, and steel moment frames. Cantilever deck elevations varied from 3 feet to nearly 20 feet and were supported by OMF (Ordinary Moment Frames). Above these, SMF (Special Moment Frames) were integrated into GLB (glulam beam) floor framing systems, requiring intricate coordination between materials and structural systems.

ISE employed a combination of analytical tools to ensure compliance and performance. Frame stiffness values (K) were calculated from first principles and validated using RISA 3D, a structural analysis software. The slenderness ratio of the columns often governed frame performance, and in some instances, designs that passed preliminary Excel-based analysis failed under more rigorous RISA testing due to slender column sections.

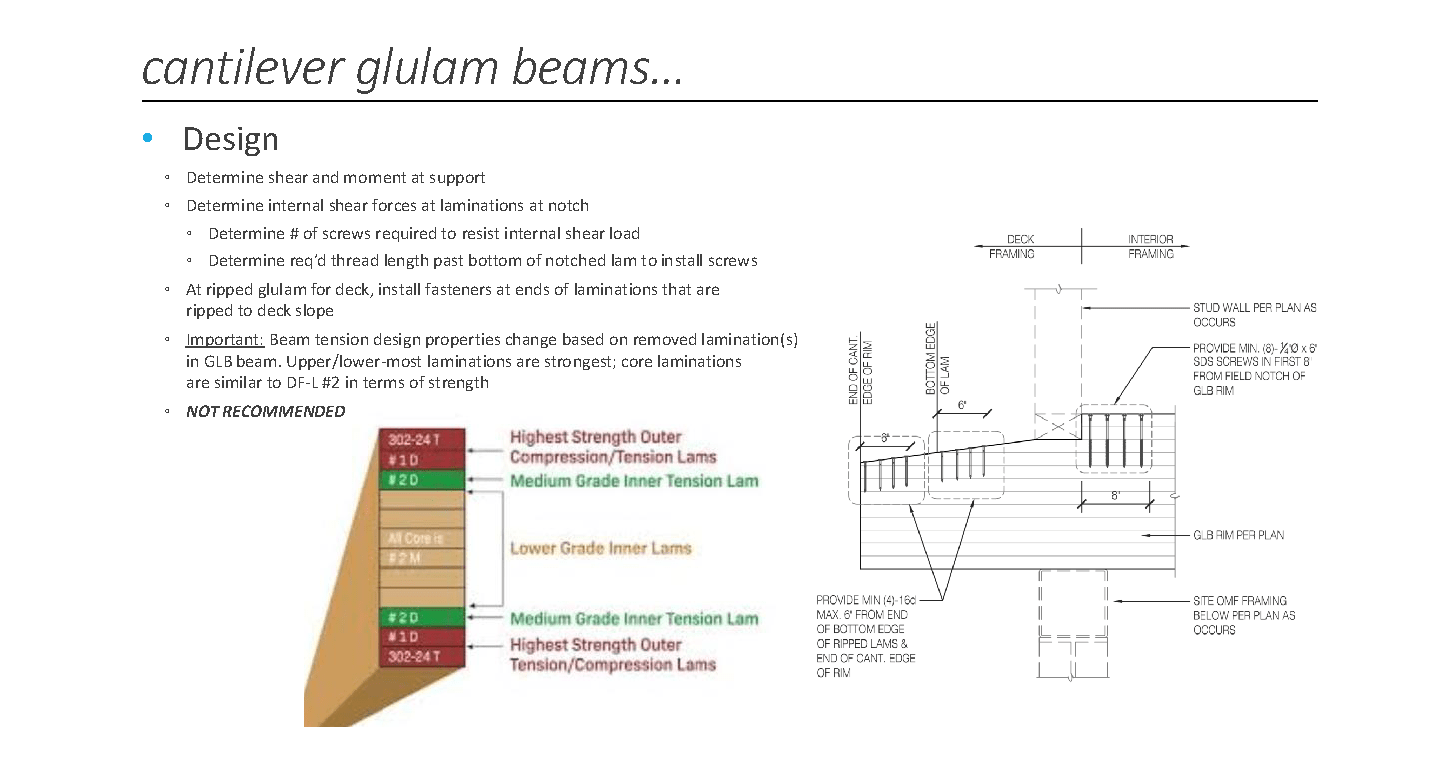

Cantilevered Glulam Beams

The cantilevered glulam beams presented another layer of complexity. These elements were subject to both vertical and lateral loading, requiring detailed analysis of internal shear forces, particularly at notched areas. ISE determined the number and thread length of screws needed to resist internal shear loads and specified installation requirements based on the specific lamination configurations of each beam. A critical finding during this process was the impact of removing outermost laminations, which significantly reduced the tensile strength of the beam. This insight led ISE to advise against such beam modifications whenever possible.

Regulatory and Construction Hurdles

The construction phase of Montage Healdsburg was far from straightforward. The project experienced delays that exceeded even those caused by the 2020 COVID-19 pandemic. The primary culprit: environmental compliance violations. The site was issued 34 state and federal water regulation violations, primarily related to Storm Water Pollution Prevention Plan (SWPPP) non-compliance, totaling \$6.4 million in fines. These infractions earned the project a record with the North Coast Water Board and required additional construction shutdowns, inspections, and remedial measures, compounding project delays.

Moreover, construction was challenged by proximity to the 2019 Kincade Fire, which burned to within 1.5 miles of the eastern edge of the site. Despite these hurdles, the resort opened to the public on January 28, 2021.

Coordination and Communication

The coordination effort required to bring Montage Healdsburg to life was immense. The final Request for Information (RFI) count reached 879, with approximately 100 requiring input from ISE. These RFIs ranged from design clarifications to construction adjustments, reflecting the complex interplay between architectural ambition, engineering practicality, and site realities.

ISE’s role extended beyond design, encompassing ongoing construction administration services. These efforts were essential to maintaining project momentum, particularly during transitions between modular and panelized construction methods and while navigating environmental compliance issues.

Recognition and Legacy

Despite the challenges, the finished resort stands as a testament to engineering ingenuity and collaborative perseverance. By 2022, Montage Healdsburg was ranked the #2 hotel in Northern California by Condé Nast Traveler and has welcomed celebrity guests such as Justin Bieber and Taylor Lautner.

ISE’s engineering expertise was instrumental in enabling the architectural vision to materialize on a difficult site with a demanding schedule and complex regulatory environment. The project exemplifies how thoughtful engineering, when combined with adaptability and rigorous analysis, can overcome formidable obstacles to deliver landmark results.

Conclusion

The Montage Healdsburg project demonstrates the multifaceted role of structural engineers in modern hospitality development. ISE’s contributions—ranging from advanced frame design and glulam beam analysis to SWPPP compliance support and post-permit coordination—were vital to the project’s success. With a design period that spanned multiple iterations, a switch from modular to panelized systems, and site conditions that tested even the most robust engineering practices, Montage Healdsburg now stands not just as a luxury resort, but as a case study in structural problem-solving.